Case studies from operational practice

The following examples are real-life projects in antenna manufacturing.

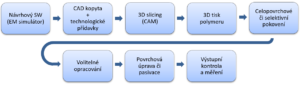

The aim is to outline the basic technological process from design, production preparation to the final component.

Both manufacturing technologies, i.e. 3D printing and electroforming, require a specific approach to component design with respect to downstream technological operations.

1) Funnel antennas

The solution is based on the use of 3D printing from PA12 material and MJF or SLS printing technology.

The standard 3D model of the WR90 funnel antenna has been modified in CAD software with 0.1 mm wall shrinkage and technological additions for the suspension technology.

This was followed by 3D printing of the part in PA12 material, silver plating of the polymer surface and 0.1 mm thick copper plating.

The resulting antenna exhibits much lower weight, lower manufacturing costs and short production times.

At the same time, additional mechanical elements, grips, etc. can be efficiently integrated into the antenna.

Fig. 1 Schematic representation of the manufacture of a funnel antenna

Fig. 2 Funnel antennas

2) Waveguide transition

The rectangle-circle waveguide transition is made of three components.

The flanges are milled from brass and the waveguide transition itself is made of electroformed copper with a wall thickness of 1 mm.

The basis for the production is the preparation of the core of the waveguide transition, which forms the hoof for the subsequent electroforming.

In this case, Plexiglas (polymethyl methacrylate) was used, which was machined to the desired geometric transition shape, including technological additions.

This was followed by polishing to a high gloss.

The next operations were silvering of the hoof and thick copper plating with a wall thickness of 1 mm.

Further machining of the hoof (milling machine and lathe), separation of the hoof, joining of the copper blank with the flanges and silver soldering were carried out.

Finally, the entire waveguide transition was chemically silver-plated, which resulted in the entire transition cavity being silver-plated with the same layer of metal to a high shine.

Stainless steel provides a similar service to Plexiglas for mass production.

Due to the geometric precision achieved and the quality of the internal surfaces, electroforming is an unrivalled production technology for many applications.

Fig. 3 Schematic representation of the production of the waveguide transition

Fig. 4 Waveguide transition

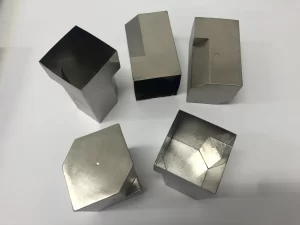

3) Antenna – square waveguide

Precision microwave antennas can also be produced in the reverse way, where a thick metal layer is excluded on the production hoof, and this method is particularly suitable for mass production. Thanks to this, it is possible to produce several antennas at the same time by electroforming in an electrolyser (electroplating bath). The basis for production is a hoof made of stainless steel, including technological additions. The hoof was then plated with a thick layer of copper 0.4 mm thick. After removing the hoof, the copper blank was machined and coated with a surface treatment, which in this case is chemical nickel, which guarantees uniform plating even inside the bellows cavity. The same procedure can be used to realise all shapes of antennas or other structures that can be demoulded – i.e. to separate the production hoof from the deposited metal part. In the case of requirements for negative structures inside the cavity (e.g. corrugated waveguides or waveguide filters in the design of internal plugs), which would prevent deformation, the hooves are realized, for example, as meltable or chemically soluble structures (e.g. from aluminium alloys).

Fig. 5 Schematic representation of square waveguide production

Fig. 6 Square waveguides

Conclusion

The combination of 3D printing and electroforming offers a unique opportunity for the production of standard microwave components as well as for the production of completely new structures that would otherwise not be possible with conventional manufacturing processes.

This opens up completely new opportunities for highly efficient mass production of existing components, but also for the development of microwave components of the future.

In fact, additional components, semi-finished products or auxiliary materials can be added to the 3D printing of polymers or metals and all of them can be “galvanised” with copper or nickel into a single assembly using electroforming.

The design palette is very varied: polymers, metals, ferrites, dielectrics (glass, ceramics, Teflon), heating or cooling circuits ... References [1] Vojtěch L., Company documentation [2] Vojtěch, L., Tuček, R.: ELFORMPLATE Unique technology of electroplating of plastic components made by 3D printing and glass ceramic components, DPS 1/2023, ISSN 1805-5044.

Electroforming s.r.o. – We meet individual requirements from development to production.