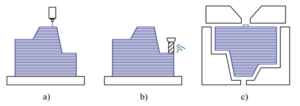

Additive, subtractive and formative technologies are three types of manufacturing methods in engineering that are used to produce a wide range of products. Each of these methods (schematically shown in Figure 1) has specific characteristics, advantages and limitations that determine its suitability for a given application. Let us take a closer look at the characteristics of each of these methods.

Fig. 1 Basic manufacturing processes [1]

a) additive manufacturing, b) subtractive manufacturing, c) formative manufacturing

Additive technologies

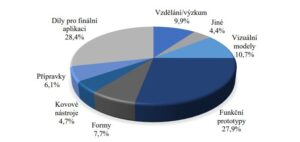

ASTM (The American Society for Testing and Materials), according to ISO/ASTM 52900, introduces and defines terms used in the field of additive technologies. According to this standard, additive manufacturing is defined as a process that creates three-dimensional objects from 3D virtual models by sequentially depositing individual material elements and then joining them together. [2] Additive technologies are generally characterized by their high flexibility in changing the manufacturing geometry of parts, making them ideal for rapid prototyping, which can be further used, for example, for visual testing of the design or geometry of a part. The following graph in Figure 2 shows the percentage of applications in which additive manufacturing is used to produce parts. These values show that the largest share of the use of additive technologies is the creation of functional parts for the final application (sale of parts and their use by the end customer). The second most common activity is prototyping. [2, 3]

Fig. 2 Percentage of additive manufacturing applications [3]

Unlike polymer injection moulding or metal casting, additive manufacturing does not require the production of tools (moulds), which in some cases is time consuming. As a result, 3D printing reduces costs and lead times. Parts with almost any geometry can be produced on additive technology machines, opening up new possibilities for part design. Although additive manufacturing offers many advantages over conventional manufacturing and addresses some of its limitations, it cannot completely replace it. For example, for high-volume production, technologies such as casting or injection moulding are still preferred, which (despite the large initial investment in moulds) are worthwhile due to the production of large quantities of products. In general, parts made by additive manufacturing do not achieve the same surface quality and precision as is achieved by machining, for example. [1, 3, 4]

Classical additive methods include FDM (Fused Deposition Modeling), SLA (Stereolithography) or SLS (Selective Laser Sintering).

Subtractive technologies

With subtractive technologies, the desired product geometry is achieved by successive removal of material from the blank block using a tool. This group of technologies can be divided into three subcategories: [5, 6].

- conventional machining: the workpiece material is removed in chip form by the relative motion of the tool cutting edge,

- abrasive processes: the material of the workpiece is removed in the form of small particles by the relative movement of the abrasive material (grinding stone, wheel, paste, etc.),

- Unconventional machining: machining occurs by light, chemical, thermal or electrical energy (or combinations thereof) without physical contact between the tool and the workpiece.

The main advantages of subtractive technologies include, for example, the production of parts with high geometric accuracy, surface integrity and smooth surfaces. All this with high reproducibility of production. Subtractive processes can be used to machine different types of materials such as metals, ceramics, plastics or composites. Typical representatives of these technologies are for example milling, turning, drilling or electrical discharge machining (EDM) [5].The disadvantages of subtractive technologies include for example the high material waste that occurs as a result of material removal. These technologies may require sophisticated and expensive machines that can be high maintenance. Subtractive technologies are also limited in the production of very complex shapes. [5]

Formative technologies

In formative methods, production is carried out by changing the shape of the product in a defined way, by applying external forces or heat. These methods include, for example, injection moulding, pressing, forging or rolling. These technologies are cost-effective for large production runs, reducing the cost per unit of production. Due to the repetitive process, they ensure high reproducibility and product quality [3, 5] Injection moulded plastic parts achieve higher strengths compared to parts made using 3D printing. [7] The initial investment in formative technologies is high, requiring significant costs for molds and tooling used in the manufacturing processes. Once the mould is made, mould modifications are very limited when the product design changes. [5, 8]

Sources

[1] What is 3D printing? How does 3D printing work? Hubs [online]. [vid. 2023-03-12]. Available from: https://www.hubs.com/guides/3d-printing/ [2] GEBHARDT, Andreas and Jan-Steffen HÖTTER. Additive manufacturing: 3D printing for prototyping and manufacturing. Munich : Cincinnati : Hanser Publishers ; Hanser Publications, 2016. ISBN 978-1-56990-582-1. [3] WOHLERS ASSOCIATES, ed. Wohlers report 2019: 3D printing and additive manufacturing state of the industry. Fort Collins (Colo.): Wohlers Associates, 2019. ISBN 978-0-9913332-5-7. [4] Additive manufacturing (Rapid prototyping, tooling) [online]. [accessed 2023-03-12]. Available from: http://www.custompartnet.com/wu/additive-fabrication [5] Traditional vs. Additive Manufacturing “ [online] [Accessed 2024-08-23]. Available from: https://www.pdfsupply.com/blog/index.php/2022/03/28/traditional-vs-additive-manufacturing/

[6] INASAKI, I., H. K. TÖNSHOFF, and T. D. HOWES, 1993. Abrasive Machining in the Future. CIRP Annals [online]. 42(2), 723-732 [vid. 2024-08-23]. ISSN 0007-8506. Available from: doi:10.1016/S0007-8506(07)62535-9 [7] What is the 3D Printing vs Injection Molding Cost-per-Unit Breakeven? [online] [vid. 2024-09-06]. Available from: https://www.xometry.com/resources/injection-molding/injection-molding-vs-3d-printing/

[8] Advantages of Additive Manufacturing over Conventional Manufacturing [online] [vid. 2024-08-23]. Available from: https://www.alphaprecisionpm.com/blog/advantages-of-additive-manufacturing-over-conventional-manufacturing

Follow us on our social media where we regularly share examples of our projects, industry news and interesting facts! Find us on Facebook and Instagram.